Dodge Journey: Schematics and diagrams

40/41TE - WITH VARIABLE LINE PRESSURE

Fig. 181: Identifying Line Pressure - Park & Neutral

Fig. 182: Identifying Line Pressure - Reverse

Fig. 183: Identifying Line Pressure - First Gear (Drive)

Fig. 184: Identifying Line Pressure - Second Gear (Drive)

Fig. 185: Identifying Line Pressure - Second Gear EMCC (Drive)

Fig. 186: Identifying Line Pressure - Direct Gear (Drive)

Fig. 187: Identifying Line Pressure - Direct Gear EMCC (Drive)

Fig. 188: Identifying Line Pressure - Fourth Gear Overdrive (Drive)

Fig. 189: Identifying Line Pressure - Fourth Gear Overdrive EMCC (Drive)

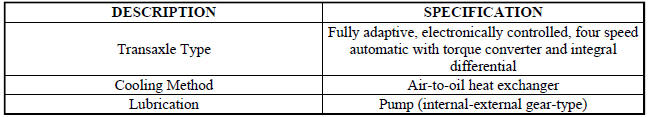

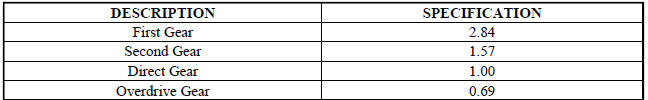

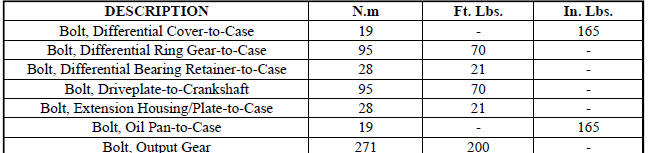

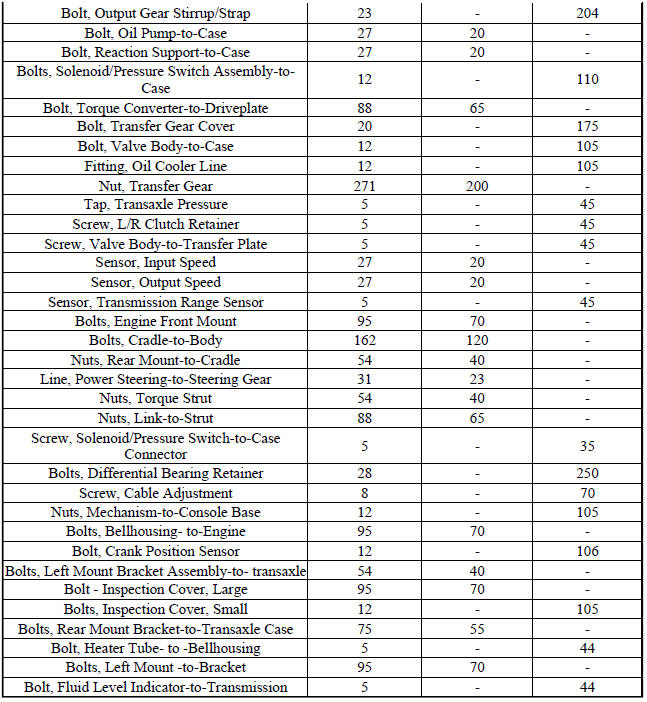

SPECIFICATIONS

GENERAL SPECIFICATIONS

GEAR RATIOS

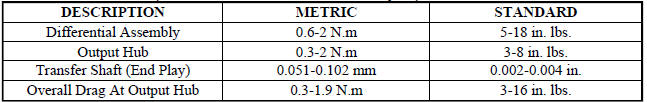

BEARING SETTINGS (END PLAY AND TURNING TORQUE)

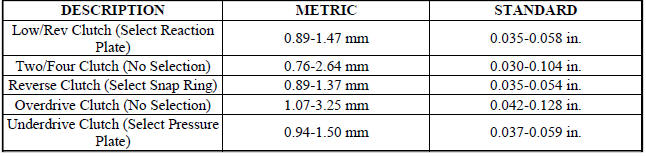

CLUTCH CLEARANCES

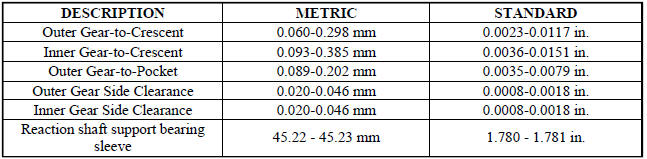

OIL PUMP CLEARANCES

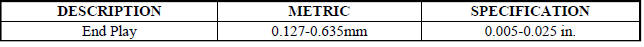

INPUT SHAFT

TORQUE SPECIFICATIONS

SPECIAL TOOLS

Fig. 190: Puller C-637

Fig. 191: Pressure Gauge (High) C-3293SP

Fig. 192: Dial Indicator C-3339

Fig. 193: Oil Pump Puller C-3752

Fig. 194: Seal Puller C-3981B

Fig. 195: Universal Handle C-4171

Fig. 196: Seal Installer C-4193A

Fig. 197: Adapter C-4996

Fig. 198: Remover Kit L-4406

Fig. 199: Gear Puller L-4407A

Fig. 200: Bearing Installer L-4410

Fig. 201: Gear Checking Plate L-4432

Fig. 202: Bearing Puller L-4435

Fig. 203: Differential Tool L-4436A

Fig. 204: Special Jaw Set L-4518

Fig. 205: Installer L-4520

Fig. 206: Thrust Button L-4539-2

Fig. 207: Adapter L-4559

Fig. 208: Adapter L-4559-2

Fig. 209: Bearing Splitter P-334

Fig. 210: Puller Set 5048

Fig. 211: Remover/Installer 5049-A

Fig. 212: Installer 5050A

Fig. 213: Installer 5052

Fig. 214: Compressor 5058A

Fig. 215: Compressor 5059-A

Fig. 216: Installer 5067

Fig. 217: Pliers 6051

Fig. 218: Installer 6052

Fig. 219: Installer 6053

Fig. 220: Button 6055

Fig. 221: Plate 6056

Fig. 222: Disk 6057

Fig. 223: Installer 6061

Fig. 224: Remover 6062-A

Fig. 225: Holder 6259

Fig. 226: Bolt 6260

Fig. 227: Installer 6261

Fig. 228: Tip 6268

Fig. 229: Remover/Installer 6301

Fig. 230: Remover/Installer 6302

Fig. 231: Installer 6536-A

Fig. 232: Puller 7794-A

Fig. 233: End Play Socket Set 8266

Fig. 234: Input Clutch Pressure Fixture 8391

Fig. 235: Driveline Support Table 8874

Fig. 236: Driveline Support Fixture 8534B

Fig. 237: Steering Shaft Roll Pin Remover/Installer 6831A

Installation

Installation

Fig. 164: Removing/Installing Bellhousing Upper & Lower Bolts

NOTE: If transaxle assembly is being replaced or overhauled (clutch

and/or seal

replacement), it is necessary to perform th ...

Accumulator

Accumulator

DESCRIPTION

Fig. 238: Identifying Underdrive & Overdrive Accumulators

- RETURN SPRING

- UNDERDRIVE CLUTCH ACCUMULATOR

- SEAL RING (2)

- OVERDRIVE CLUTCH ACCUMULATOR

The 41TE underd ...

See also:

Switch, heated seat

DESCRIPTION

Fig. 10: Locating Accessory Switch Bank Module

Two heated seat switches are located in the center stack of the instrument

panel. The switches are located on the

outer edges of the A ...

Installation

1. Guide the trailing end of the parking brake cable along the inboard side

of the axle trailing arm up to the

rear brake caliper. Make sure the cable is routed between the brake line and the

tra ...

Adjustments

ADJUSTMENT - LATE PRODUCTION TYPE ONLY

Two unique brake lamp switches are used in this vehicle, depending upon

whether the vehicle was built during

early or late production. These switches are not ...