Dodge Journey: 40/41TE Transaxle general diagnosis, road test

40/41TE TRANSAXLE GENERAL DIAGNOSIS

NOTE: Before attempting any repair on a 40/41TE four-speed automatic transaxle, check for Diagnostic Trouble Codes (DTC's) using the scan tool.

Transaxle malfunctions may be caused by these general conditions:

- Poor engine performance

- Improper adjustments

- Hydraulic malfunctions

- Mechanical malfunctions

- Electronic malfunctions

Diagnosis of these problems should always begin by checking the easily accessible variables: fluid level and condition, gearshift cable adjustment. Then perform a road test to determine if the problem has been corrected or that more diagnosis is necessary. If the problem persists after the preliminary tests and corrections are completed, hydraulic pressure checks should be performed.

ROAD TEST

Prior to performing a road test, verify that the fluid level, fluid condition, and linkage adjustment have been approved.

During the road test, the transaxle should be operated in each position to check for slipping and any variation in shifting.

If the vehicle operates properly at highway speeds, but has poor acceleration, the converter stator overrunning clutch may be slipping. If acceleration is normal, but high throttle opening is needed to maintain highway speeds, the converter stator clutch may have seized. Both of these stator defects require replacement of the torque converter and thorough transaxle cleaning.

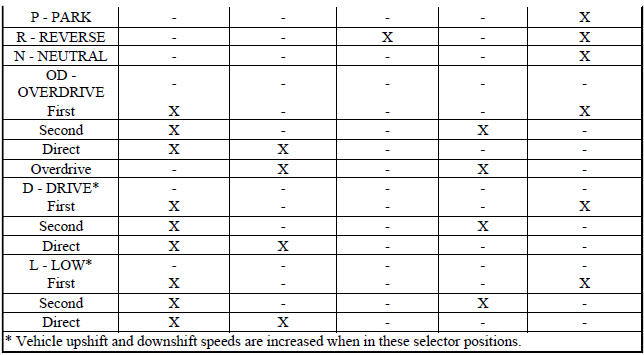

Slipping clutches can be isolated by comparing the "Elements in Use" chart with clutch operation encountered on a road test. This chart identifies which clutches are applied at each position of the selector lever.

A slipping clutch may also set a DTC and can be determined by operating the transaxle in all selector positions.

ELEMENTS IN USE AT EACH POSITION OF SELECTOR LEVER

The process of elimination can be used to detect any unit which slips and to confirm proper operation of good units. Road test analysis can diagnose slipping units, but the cause of the malfunction cannot be determined.

Practically any condition can be caused by leaking hydraulic circuits or sticking valves.

Hydraulic pressure tests

Hydraulic pressure tests

Fig. 4: Identifying Transmission Electrical Connectors

NOTE: Before preforming the hydraulic pressure tests be certain to

disconnect the

Variable Line Pressure (VLP) electrical connector (2 ...

See also:

Uconnect™ Multimedia (SATELLITE RADIO) — IF EQUIPPED

(REN/REQ/RER/RES/REU/RBZ RADIOS ONLY)

Satellite radio uses direct satellite-to-receiver broadcasting

technology to provide clear digital sound, coast to

coast. The subscription service provider is Sirius Satellite

Radio. This service o ...

ROOF LUGGAGE RACK — IF EQUIPPED

The roof rack cross rails and side rails are designed to

carry cargo weight. The load must not exceed 150 lbs

(68 kg), and it should be distributed uniformly over the

cross rails. In addition, the ...

Intermediate shaft, diesel

REMOVAL

2.0L DIESEL

1. Remove the right half shaft.

Fig. 50: 2.0L Diesel Right Half Shaft Components

2. Remove the two intermediate shaft bolts (1).

3. Remove the intermediate shaft (2).

...