Dodge Journey: Specifications

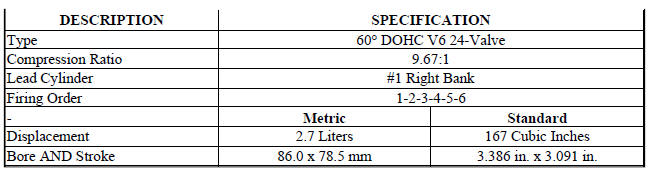

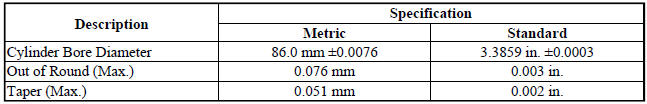

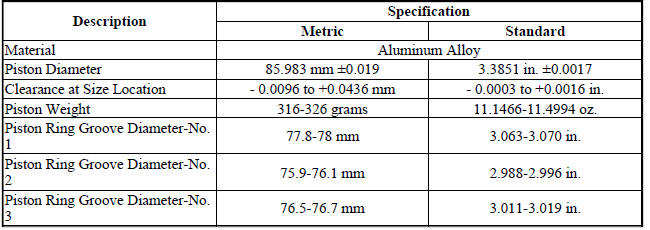

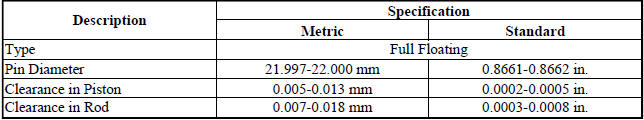

2.7L ENGINE

GENERAL SPECIFICATIONS

CYLINDER BLOCK

PISTONS

PISTON PINS

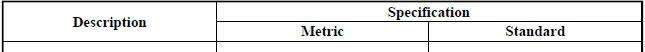

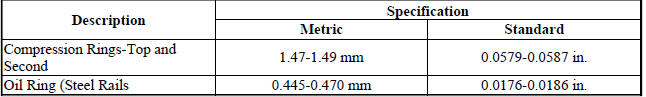

PISTON RINGS

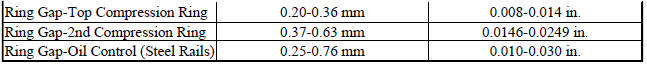

PISTON RING SIDE CLEARANCE

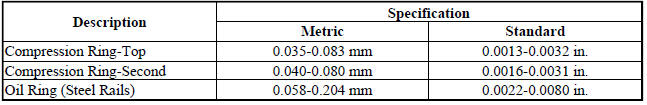

PISTON RING WIDTH

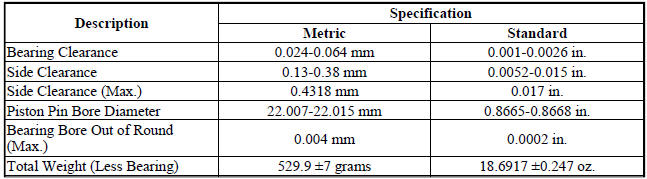

CONNECTING RODS

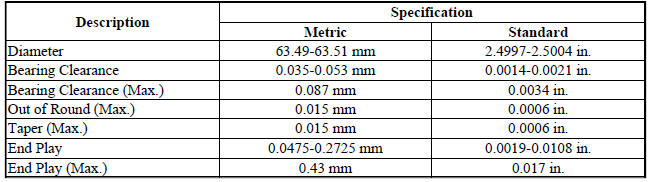

CRANKSHAFT MAIN BEARING JOURNALS

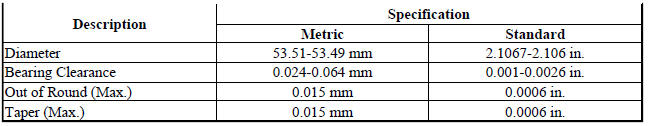

CONNECTING ROD JOURNALS

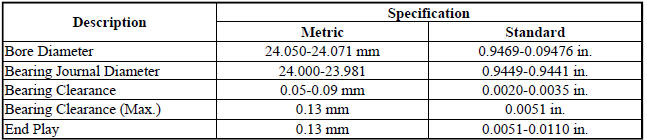

CAMSHAFT

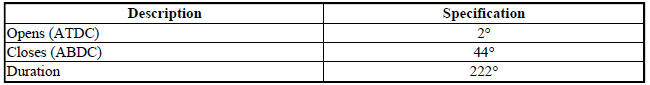

VALVE TIMING-INTAKE VALVES

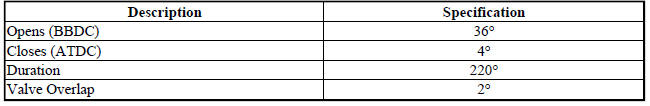

VALVE TIMING-EXHAUST VALVES

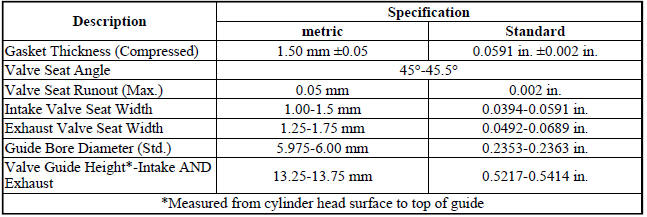

CYLINDER HEAD

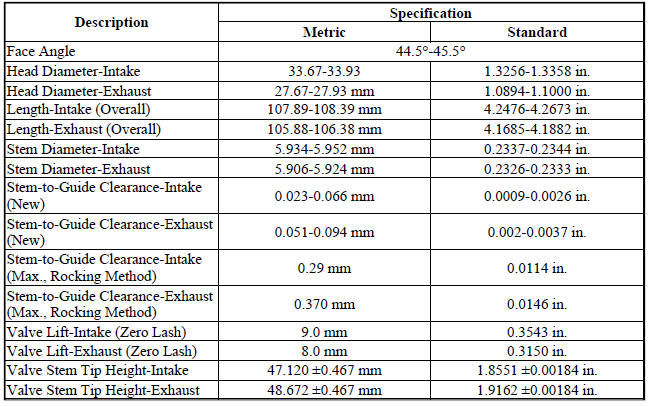

VALVES

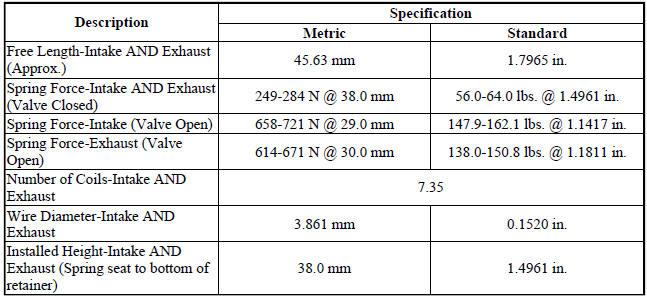

VALVE SPRING

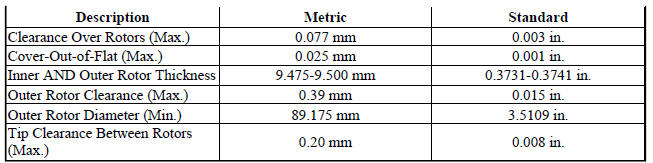

OIL PUMP

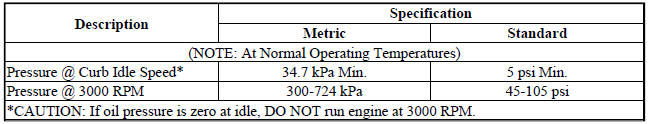

OIL PRESSURE

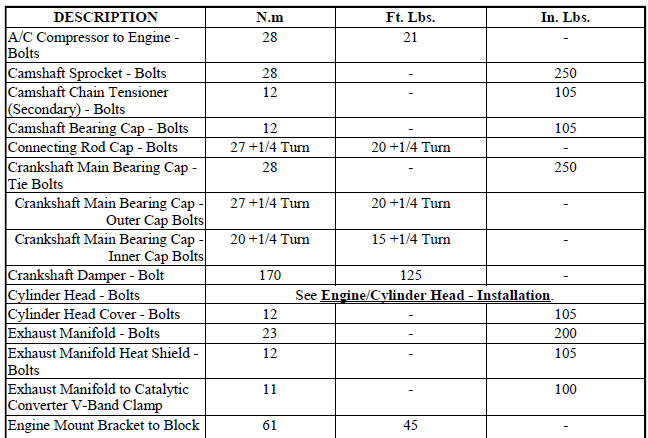

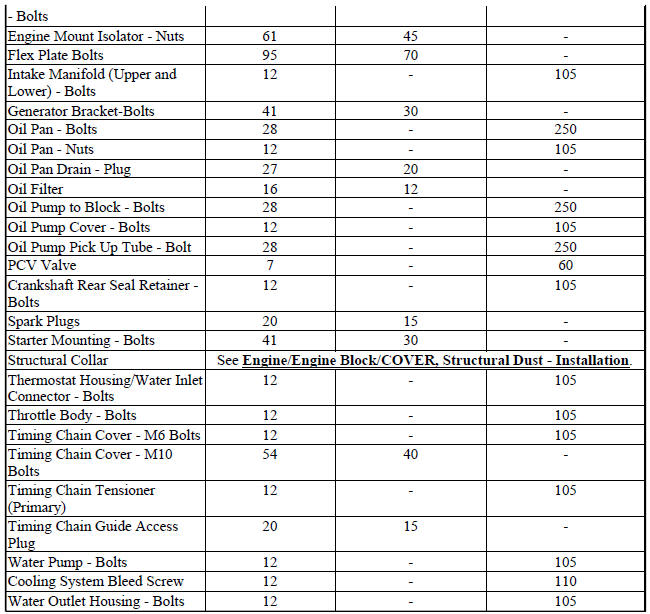

TORQUE

SPECIAL TOOLS

2.7L ENGINE

Fig. 53: Dolly 6135

Fig. 54: Cradle 6710

Fig. 55: Post Kit Engine Cradle 6848

Fig. 56: Disconnect Tool, 6638A

Fig. 57: Puller 8454

Fig. 58: Crankshaft Damper Remover Insert 8194

Fig. 59: Crankshaft Damper Installer Screw 8179

Fig. 60: Crankshaft Damper Installer 6792-1

Fig. 61: Crankshaft Seal Remover 6771

Fig. 62: Crankshaft Seal & Sprocket Installer 6780-1

Fig. 63: Crankshaft Seal Protector 6780-2

Fig. 64: Puller 5048

Fig. 65: Puller Adaptor 8539

Fig. 66: Crankshaft Rear Seal Guide 6926-1 & Installer 6926-2

Fig. 67: Driver Handle C-4171

Fig. 68: Crankshaft Real Seal Retainer Alignment Fixture 8225

Fig. 69: Timing Chain Tensioner Resetting Gauge 8186

Fig. 70: Dial Indicator C-3339

Fig. 71: Valve Spring Compressor 8215-A

Fig. 72: Adaptor 8216-A

Fig. 73: Valve Spring Compressor C-3422-D

Fig. 74: Valve Spring Adapter 6526

Fig. 75: Valve Spring Tester C-647

Fig. 76: Valve Spring Compressor MD-998772-A

Fig. 77: Valve Spring Adapter 6527

Fig. 78: Indicator Bore Size C-119

Fig. 79: Connecting Rod Installation Guides 8189

Fig. 80: Main Bearing Remover/Installer C-3059

Fig. 81: Pressure Gauge C-3292

Fig. 82: Adapter 8406

Fig. 83: Cooling System Tester 7700

Fig. 84: Combustion Leak Tester C-3685-A

Installation

Installation

Fig. 32: Brake Booster Vacuum Hose

1. Position engine/transaxle assembly under vehicle and slowly lower vehicle

in short length spans. Inspect

at each interval for potential engine or transaxle ...

See also:

Description, Operation

DESCRIPTION

A diesel particulate filter (DPF) is installed for exhaust gas

after-treatment. The DPF filters, stores and burns

particulate matter (soot) that is generated during the combustion proc ...

Operation

The left (lighting) multi-function switch uses resistor multiplexing to

control the many functions and features it

provides using a minimal number of hard wired circuits. The switch receives

clea ...

Insulator, engine mount, front

Removal

1. Raise vehicle.

Fig. 222: Belly Pan

- belly pan fasteners

- belly pan

2. Remove the belly pan (2).

Fig. 223: Front Engine Mount Through Bolt

3. Remove front mount to bracket ...