Dodge Journey: Description, Operation, Diagnosis and Testing

DESCRIPTION

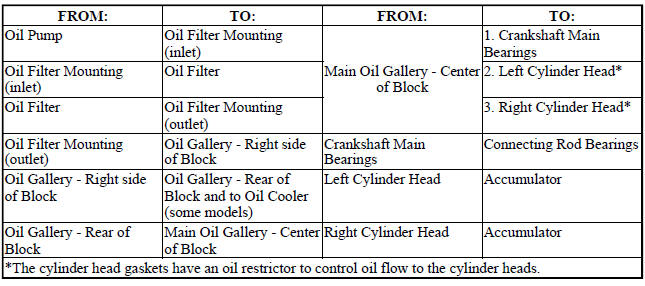

The lubrication system is a full-flow filtration, pressure feed type. The oil pump body is mounted to the engine block. The pump inner rotor is driven by the crankshaft. A structural windage tray is used to increase power by minimizing oil windage at high engine RPM. An engine oil cooler is used on some models.

OPERATION

Oil from the oil pan is pumped by a gerotor type oil pump (3) directly coupled to the crankshaft. Oil pressure is controlled by a relief valve mounted inside the oil pump housing.

Fig. 247: Cylinder Block Oil Lubrication System

- - TO RIGHT CYLINDER HEAD

- - TO LEFT CYLINDER HEAD

- - OIL PUMP

- - OIL PICKUP TUBE

- - OIL FILTER

- - TO CRANKSHAFT MAIN JOURNALS

- - MAIN OIL GALLERY

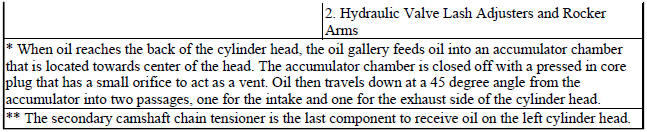

Fig. 248: Cylinder Head Oil Lubrication System - Left Side

- - CAM JOURNALS

- - OIL FEED TO CAMSHAFT (SECONDARY) CHAIN TENSIONER

- - LASH ADJUSTER BORES

- - OIL FEED FROM BLOCK

- - VENT HOLE

- - ACCUMULATOR

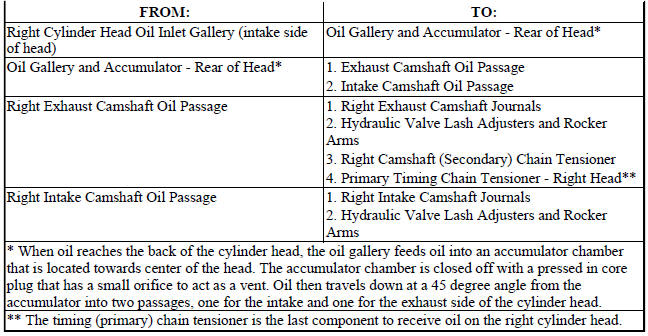

Fig. 249: Cylinder Head Oil Lubrication System - Right Side

- - OIL FEED TO CAMSHAFT (SECONDARY) CHAIN TENSIONER

- - OIL FEED TO TIMING CHAIN (PRIMARY) TENSIONER

- - CAM JOURNALS

- - ACCUMULATOR

- - VENT HOLE

- - OIL FEED FROM BLOCK

- - LASH ADJUSTOR BORES

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

1. Remove the oil pressure switch.

2. Install oil pressure test gauge assembly, Special Tools C-3292A with 8406 adaptor.

3. Start engine and monitor gauge readings.

CAUTION: If oil pressure is 0 at idle, Do Not Run engine at 3000 RPM

4. Oil Pressure (engine at operating temperature): Curb Idle 34.5 kPa (5 psi) minimum 3000 RPM 300-724 kPa (45-105 psi).

5. If oil pressure is 0 at idle. Shut off engine, check for pressure relief valve stuck open or a clogged oil pickup screen.

6. Install oil pressure switch after testing is completed.

Lubrication

Lubrication

...

Cooler and lines, oil

Cooler and lines, oil

Description

Fig. 250: Oil Cooler Fasteners

Some 2.7L engines may be equipped with an engine oil cooler (2) that is

mounted to the rear transmission

mount bracket. Oil lines route oil from the e ...

See also:

Installation

CAUTION: Be certain to adjust the refrigerant oil level when

servicing the A/C

refrigerant system. Failure to properly adjust the refrigerant

oil level will prevent the A/C system fro ...

Installation

LEFT-HAND-DRIVE

Fig. 140: PEDAL AND BOOSTER MOUNTING - LHD

1. Carefully install the brake pedal and bracket assembly (1) in the vehicle

lining up the bracket with the

power brake booster mounti ...

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow, it

can often be moved by a rocking motion. Turn your

steering wheel right and left to clear the area around the

front wheels. Then shift back an ...