Dodge Journey: Installation

Fig. 67: Seal Protector

- - HALFSHAFT

- - SEAL PROTECTOR

1. Install driveline module to transmission jack. Secure module to jack.

2. Using Seal Protector 9099 (2), load halfshafts to differential, one side at a time. Clean tool and seal area to prevent debris intrusion.

Fig. 68: Support Module With Jack

- - DRIVELINE MODULE

- - TRANSMISSION JACK

3. Raise driveline module (1) into position.

Fig. 69: Removing /Installing Propeller Shaft

4. Align marks (4) on propeller shaft rubber coupler (1) to rear axle input flange (5).

5. Install three rear propeller shaft to rear axle retaining bolts (3) but do not tighten at this time.

Fig. 70: RDA To Crossmember Bolts

6. Install the RDA - to - crossmember mounting bolts (1) and tighten to 102 N.m (75 ft. lbs.).

Fig. 71: Rear RDA Module-To-Crossmember Bolt

7. Install the rear RDA - to - crossmember mounting bolt (2) to 102 N.m (75 ft. lbs.)

8. Tighten propeller shaft-to-driveline module bolts to 58 N.m (43 ft.lbs.).

9. Raise exhaust system into position and install hanger/brackets.

10. Fill differential with 0.7L (0.74 Quarts) of Mopar Gear and Axle Lubricant (75W-90).

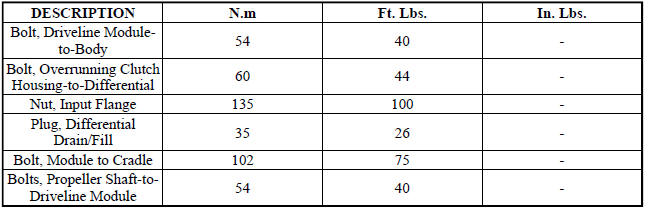

SPECIFICATIONS

SPECIAL TOOLS

Fig. 72: Flange Wrench, C-3281

Fig. 73: Installer 8493

Fig. 74: Installer 9231A

Fig. 75: Protector, 9099

Fig. 76: Universal Handle C-4171

Removal

Removal

Fig. 60: Support Module With Jack

- DRIVELINE MODULE

- TRANSMISSION JACK

NOTE: Rear suspension and drivetrain design require this procedure to

be performed

on a "drive-on" ...

Case assembly, differential

Case assembly, differential

DESCRIPTION

The differential gear system divides the torque between the axle shafts. It

allows the axle shafts to rotate at

different speeds when turning corners.

Each differential side gear is s ...

See also:

TILT/TELESCOPING STEERING COLUMN — IF EQUIPPED

This feature allows you to tilt the steering column

upward or downward. It also allows you to lengthen or

shorten the steering column. The tilt/telescoping control

handle is located below the steer ...

Diagnosis and testing

COMMON PROBLEM CAUSES

The majority of transaxle malfunctions are a result of:

Insufficient lubrication

Incorrect lubricant

Misassembled or damaged internal components

Improper operation

...

Removal

2.7L ENGINE

Fig. 22: Belly Pan

- BELLY PAN

- EXHAUST EXTENSION PIPE

1. Remove the belly pan (2).

Fig. 23: 2.7L Extension Pipe

2. Remove the fasteners (1), and remove the exhaust extens ...