Dodge Journey: Installation

Fig. 40: Seal Protector

- - HALFSHAFT

- - SEAL PROTECTOR

1. Install halfshaft to hub/bearing assembly. Install hub nut and washer but do not tighten at this time.

2. Using Seal Protector 9099 (2) , install halfshaft (1) to differential assembly. Clean tool and seal area to prevent debris intrusion.

Fig. 41: Module Mounting Bolt

- - BOLT

- - DRIVELINE MODULE

3. Raise driveline module into position. Install module mounting bolt (1) .

Fig. 42: Module Mounting Bolts

- - BOLT (2)

- - DRIVELINE MODULE

4. Install remaining two module mounting bolts (2) .

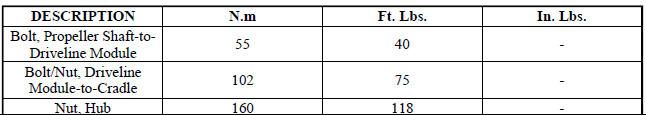

5. Torque module-to-cradle bolts to 102 N.m (75 ft. lbs.) 6. Torque the halfshaft/hub nut to 160 N.m (118 ft.lbs.).

7. Install wheel center cap.

8. Check and adjust differential fluid level.

SPECIFICATIONS

SPECIAL TOOLS

Fig. 43: Protector, 9099

Removal

Removal

Fig. 35: Removing/Installing Halfshaft Nut

NOTE: Rear suspension and drivetrain design require this procedure to

be performed

on a "drive-on" hoist, as the front and rear suspensi ...

Intermediate shaft, gas

Intermediate shaft, gas

REMOVAL

2.4L

1. Remove the right half shaft.

Fig. 44: Intermediate Shaft - 2.4L

2. Remove the three intermediate shaft bolts (1).

3. Remove the intermediate shaft (2).

2.7L

1. Remove the r ...

See also:

Relay, trailer tow

DESCRIPTION

Fig. 40: Identifying Relay & Terminals

Vehicles equipped with an optional trailer tow preparation package have four

trailer tow relays, one each for the

trailer tow stop/turn ri ...

Description

Fig. 46: Left Multifunction Switch

The left (lighting) multi-function switch is located on the left side of the

steering column, just below the steering wheel. This switch is the primary

contro ...

Fascia, front lower, closeout

REMOVAL

Fig. 11: Lower Fascia

1. Remove fasteners (5) to lower closeout.

Fig. 12: Push Pins - Front Lower Fascia

2. Remove push pins (1) to lower closeout.

3. Remove the front lower fascia.

...