Dodge Journey: Installation

Fig. 137: Rear Mount Bracket

1. If transmission brackets were removed or transmission was replaced install the rear mount bracket and tighten (1) to 100 N.m (74 ft. lbs.).

Fig. 138: Front Mount Bracket

2. If transmission brackets were removed or transmission was replaced install the front mount bracket and tighten (1) to 100 N.m (74 ft. lbs.) and (2) to 133 N.m (98 ft. lbs.).

Fig. 139: Left Mount Bracket

3. If transmission brackets were removed or transmission was replaced install the left mount bracket and tighten (1) to 100 N.m (74 ft. lbs.).

Fig. 140: Bellhousing Bolts

4. Lift transmission into position.

5. Install the lower transmission bolts (2) and tighten to 58 N.m (43 ft. lbs.) torque.

Fig. 141: Rear Mount

6. Install the rear transmission mount (5) to cradle.

7. Install rear transmission mount bolts and tighten to 68 N.m (50 ft. lbs.).

8. Install the rear mount bracket to transmission bolts (2, 3) and tighten to 68 N.m (50 ft. lbs.).

9. Roll engine and transmission back into place.

10. Install rear mount through bolt (4) and tighten to 68 N.m (50 ft. lbs.).

11. Install the starter.

12. Install the transmission cross member and tighten to 68 N.m (50 ft. lbs.).

13. Install the front transmission mount through bolt (4) at this time and tighten to 50 N.m (37 ft. lbs.).

14. Remove the jacks.

15. Lower the vehicle.

Fig. 142: Bellhousing Bolts

16. Use a floor jack to raise transmission into position.

17. Install the upper transmission mount and tighten to 100 N.m (74 ft. lbs.).

18. Raise the vehicle on the hoist.

19. Install halfshafts.

20. Fill transmission fluid to proper level. See Standard Procedure .

21. Lower hoist.

22. Connect all wiring harness connectors and insure correct wiring harness is routed correctly.

Fig. 143: Hydraulic Line

23. Install shift cables (2) into bracket until a click is heard.

24. Snap the ball-socket end fittings onto the shift lever ball-studs.

25. Install the bolt for clutch hydraulic line (3) and tighten to 11 N.m (105 in. lbs.).

26. Install the clutch hydraulic line (1) to slave cylinder.

Fig. 144: Bleeder At Slave Cylinder

27. Install hydraulic line (1), bleed adaptor (2) and clip at the slave cylinder.

28. Bleed the slave cylinder.

29. Install the negative battery cable.

30. Install air cleaner assembly.

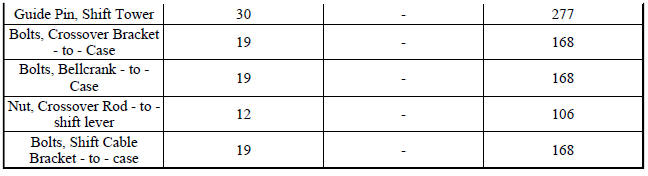

SPECIFICATIONS

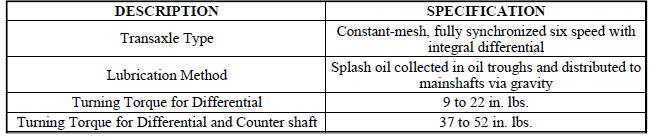

GENERAL SPECIFICATIONS

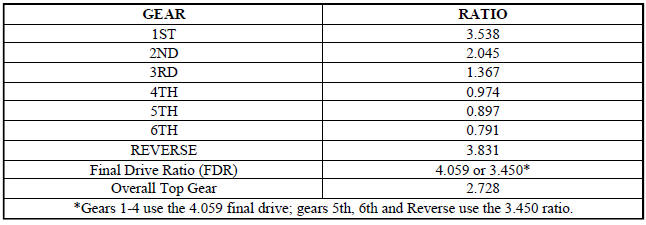

GEAR RATIOS

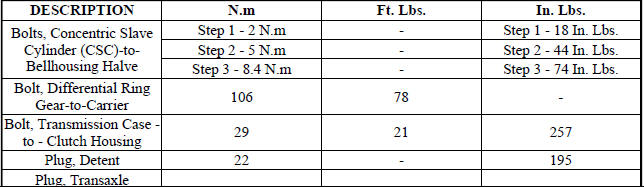

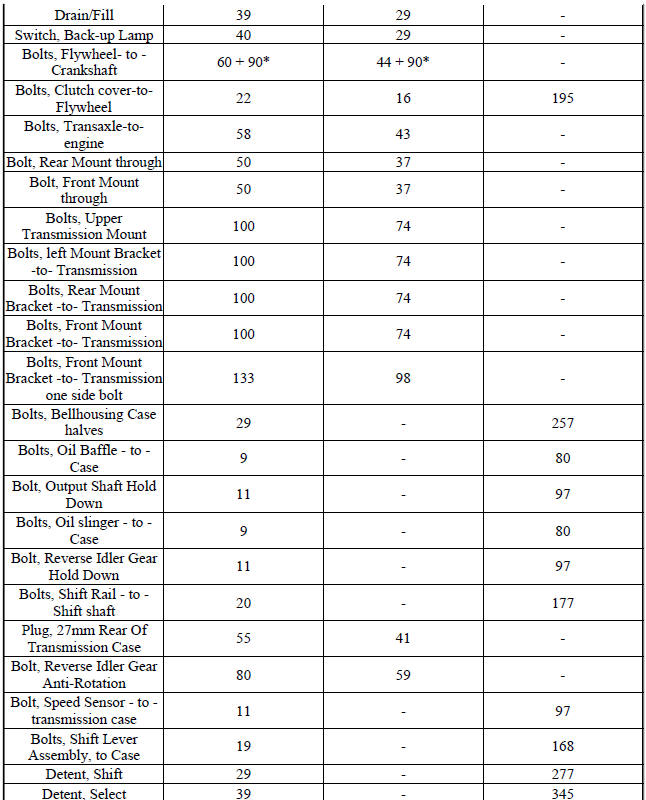

TORQUE SPECIFICATIONS

SPECIAL TOOLS

Fig. 145: Universal Handle C-4171

Fig. 146: Seal Installer 6709

Fig. 147: Remover, 9664

Fig. 148: Installer L-4520

Fig. 149: Installer 9935

Fig. 150: Installer 9928

Fig. 151: Puller 7794-A

Fig. 152: C-4657 Seal Installer

Fig. 153: Installer 9589

Fig. 154: Installer D-111

Fig. 155: Installer, Cup - D-144

Fig. 156: Bearing Splitter, P-334

Fig. 157: Fixture, 8925

Fig. 158: Puller 9647

Fig. 159: Sleeve C-3717

Fig. 160: Torque Tool C-4995

Assembly

Assembly

Fig. 65: Remove Input Shaft Bearing Cup

NOTE: Always use ATF on all moving parts during this assembly

procedure.

1. Use Bearing Cup Remover 9664 (2) and appropriate Slide Hammer (1) to

r ...

Cable, gearshift control

Cable, gearshift control

REMOVAL

Fig. 161: Shift Cables & Bracket

1. Remove the shifter.

2. Raise hood.

3. Remove the resonator.

4. Remove engine cover.

5. Remove air cleaner assembly.

6. Disconnect ne ...

See also:

Sensor, speed, output

DESCRIPTION

Fig. 378: Identifying Output Speed Sensor

- OUTPUT SPEED SENSOR

The Output Speed Sensor (1) is a two-wire magnetic pickup device that

generates an AC signal as rotation

occurs ...

Cam, turn signal cancel

DESCRIPTION

The turn signal cancel cam is concealed within the clockspring case on the

steering column. The turn signal

cancel cam consists of integral eccentrics on the outer circumference of the ...

STARTING PROCEDURES

Before starting your vehicle, adjust your seat, adjust the

inside and outside mirrors, fasten your seat belt, and if

present, instruct all other occupants to buckle their seat

belts.

WARNING:

Nev ...