Dodge Journey: Inspection, adjustments

INSPECTION

Inspect the exhaust pipes, catalytic converters, muffler, and resonators for cracked joints, broken welds and corrosion damage that would result in a leaking exhaust system. Inspect the clamps, support brackets, and insulators for cracks and corrosion damage.

ADJUSTMENTS

A misaligned exhaust system is usually indicated by a vibration, rattling noise, or binding of exhaust system components. These noises are sometimes hard to distinguish from other chassis noises. Inspect exhaust system for broken or loose clamps, heat shields, isolators, and brackets. Replace or tighten as necessary. It is important that exhaust system clearances and alignment be maintained.

Perform the following procedures to align the exhaust system:

1. Loosen clamps and support brackets.

2. Align the exhaust system starting at the front, working rearward.

3. Tighten all clamps and brackets once alignment and clearances are achieved.

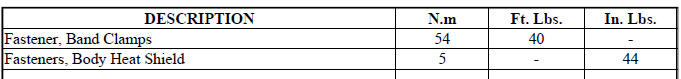

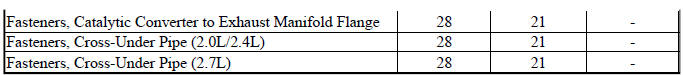

SPECIFICATIONS

TORQUE

SPECIAL TOOLS

EXHAUST SYSTEM

Fig. 3: Exhaust Cone Tool - 8404-ECT

Fig. 4: Back Pressure Test Adapter - CH8519

Fig. 5: Pressure Transducer CH7063

Diagnosis and testing

Diagnosis and testing

EXCESSIVE EXHAUST SYSTEM NOISE

CONDITION

POSSIBLE

CAUSES

CORRECTION

EXCESSIVE EXHAUST NOISE

(UNDER HOOD)

1. Exhaust manifold cracked or

broken.2. Manifold to cyl ...

Converter, catalytic

Converter, catalytic

DESCRIPTION

WARNING: The normal operating temperature of the exhaust system is

very high.

Therefore, never work around or attempt to service any part of the

exhaust system until it ...

See also:

Removal

BATTERY HARNESS

WARNING: To protect the hands from battery acid, a suitable pair

of heavy duty

rubber gloves should be worn when removing or servicing a battery.

Safety glasses als ...

Bottle, coolant recovery

Description

NON-PRESSURE

Fig. 52: NON-PRESSURE COOLANT RECOVERY CONTAINER

- COOLANT RECOVERY CONTAINER

- OVERFLOW HOSE

- RADIATOR PRESSURE CAP

The coolant recovery system used on 2.4L e ...

Installation

2.7L ENGINE

Fig. 32: Maniverter To Cross Under Fasteners

1. Install the cross under pipe (3). and the front maniverter-to-cross under

fasteners (1) and (2). Tighten to

27 Nm (20 ft. lb.).

Fi ...