Dodge Journey: Toe

Fig. 115: Steering Wheel Holding Tool

1. Center the steering wheel and lock it in place using a steering wheel clamp.

NOTE: When setting toe, make sure to set rear toe to the preferred specifications before setting front toe to the preferred specifications

NOTE: Perform the following at each rear wheel as necessary.

Fig. 116: Rear Toe Adjustment Cam Bolt

NOTE: Perform the following at each front wheel as necessary.

CAUTION: Do not twist the inner tie rod-to-steering gear boot (bellows) while turning the inner tie rod during front toe adjustment. It may be necessary to remove the clamp where the boot meets the inner tie rod.

Fig. 117: Tie Rod Jam Nut

REAR TOE

NOTE: Perform the following at each rear wheel as necessary.

Fig. 118: Rear Toe Adjustment Cam Bolt

2. While holding the cam bolt head (4) stationary, loosen the toe link mounting cam bolt nut (3).

3. Rotate the cam bolt head (4) left or right until the rear wheel toe for that rear wheel is set to the preferred specification. 4. While holding the cam bolt head (4) stationary, tighten the toe link mounting cam bolt nut (3) to 100 N.m (74 ft. lbs.).

FRONT TOE

NOTE: Perform the following at each front wheel as necessary.

CAUTION: Do not twist the inner tie rod-to-steering gear boot (bellows) while turning the inner tie rod during front toe adjustment. It may be necessary to remove the clamp where the boot meets the inner tie rod.

Fig. 119: Tie Rod Jam Nut

5. Loosen the tie rod adjusting jam nut (1). Grasp the inner tie rod (3) and rotate it one way or the other until the front wheel toe is set to the preferred specification.

6. Tighten the tie rod adjusting jam nut to of 75 N.m (55 ft. lbs.).

7. Make sure the inner tie rod-to-steering gear boot is not twisted. If removed, reinstall the clamp where the boot meets the inner tie rod.

ALL

8. Remove the steering wheel clamp.

9. Remove the alignment equipment.

10. Road test the vehicle to verify the steering wheel is straight and the vehicle does not pull or wander.

SPECIFICATIONS

WHEEL ALIGNMENT

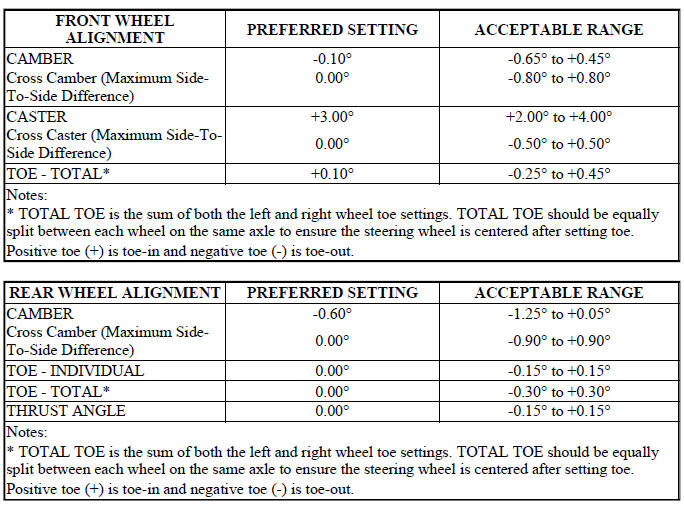

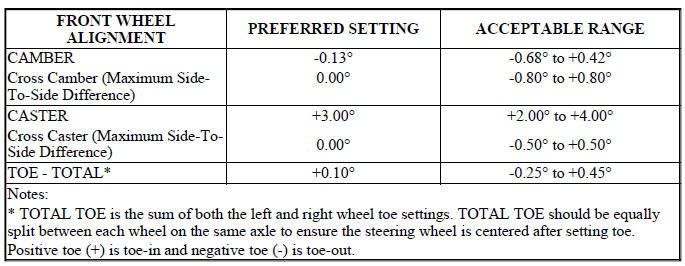

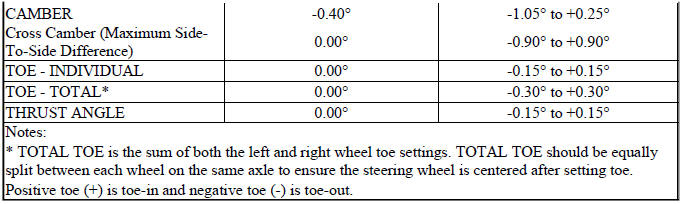

NOTE: All specifications are given in degrees.

NOTE: All wheel alignments are to be set with the vehicle at curb height.

NOTE: Curb (ride) height specifications can be found in the Curb Height Measurement procedure.

ALL EXCEPT EXPORT

EXPORT

Wheel alignment

Wheel alignment

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct the wheel alignment, the

following inspection and necessary

corrections must be made to the vehicle to ensure proper ...

Transmission

Transmission

...

See also:

Installation

LEFT-HAND-DRIVE

NOTE: The master cylinder must be bled before installing it on the

vehicle.

1. Bench bleed the master cylinder.

2. Wipe the face of the power brake booster clean where the ...

Removal

1. Raise and support the vehicle.

2. If equipped, remove the engine belly pan.

3. Remove the rear engine mount.

4. Remove the front engine mount through-bolt.

Fig. 66: Stabilizer Link Mo ...

JUMP-STARTING

If your vehicle has a discharged battery it can be jumpstarted

using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump-starting can be danger ...